Moulding and Tool Making

In this department our team produces multi-component precision tools under high technology and quality standards. More than 23 years of experience in precision tooling manufacturing catering for various customers and their complex needs.

The mould and tool making department is composed of the tool shop facilities section, here the tasks are individual as a required carried out with tools that fulfill specific functions for the manufacture of parts, moulds and precision tools production.

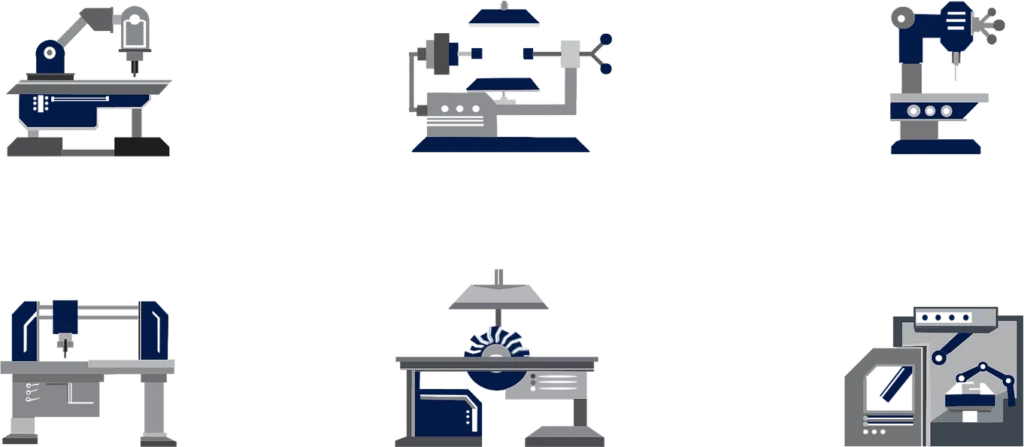

Tool Shop Facilities

This tool shop has the latest technology in our machinery for manufacturing high quality parts and elements.

- 1. Mold Flow

- 2. ProE Wildfire Workstations

- 3. ProToolmaker and Easycam

- 4. Gebr. Edechoff and Laufer Press 200 Ton

- 5. 2K Moulds

- 6. Insert Moulding

- 1. Surface and Profile Grinders

- 2. CNC Milling

- 3. High Speed Milling (5 Axis)

- 4. Radial Drill and Rough Milling.

- 5.Heat Treatment Furnaces: - Nabartherm N41 - Nabartherm N21

- 6. Electrical Discharge Machines: - Wire EDM - Spark Erosion

- 7. Laser Welding Set

- 8. Precision Measuring Equipment: - Quick Scope - Hardness Tester - CMM

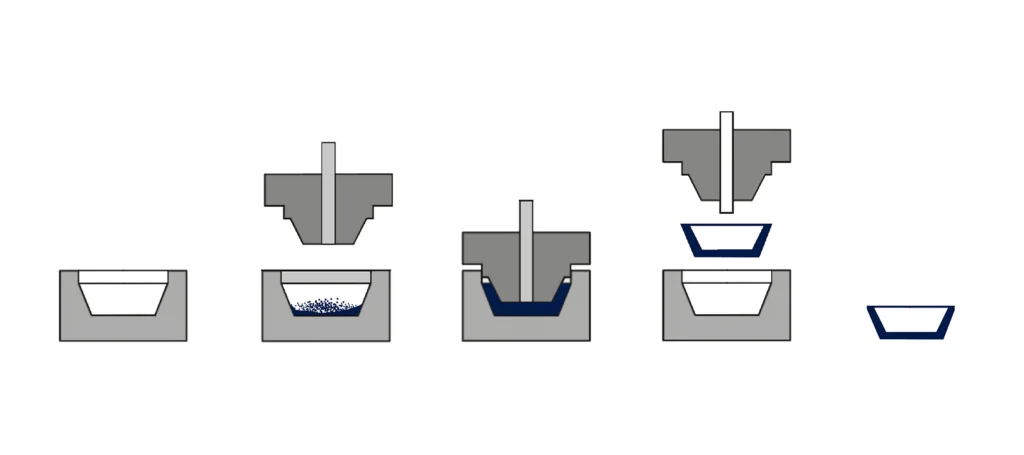

Compresing Moulding

The compressing moulding is one of the most important process in our manufacturing and mould making services, the tecnology facilities of the compressing mouldinG are part of the selectives process for manufacturing. We explain our compressing moulding technique in five stages.