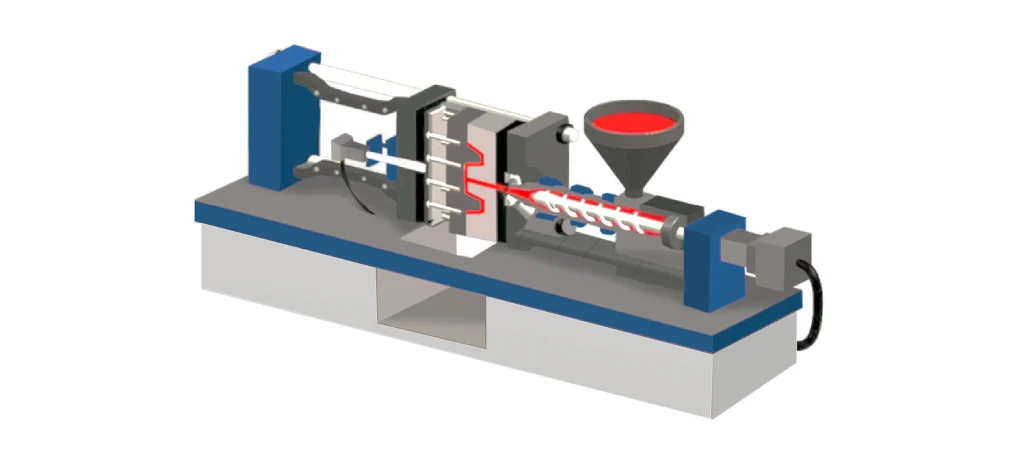

Injection Moulding

Our injection moulding department is one of the most important in our factory.

This technological process is under quality supervision team and constant improvement to achieve the highest standards in the pieces production in different materials.

The process consists in four stages in the cycle. These stages are the clamping, injection, cooling and ejection.

OUR MACHINERY Production of injection moulded products.

- Arburg 370 (100T) / 320 (75T) / 270 (50T) / 210 (35T)

- Ferromatic Milacron K-TEC 110 2 Colour

- Ferromatic Milacron K-TEC 60 2 Colour

- Ferromatic Milacron K-TEC 60

So basically the processes are for different materials as explained below:

In our injection moulding department we use injecting thermo plastics into moulds.

The 10 most commonly used plastics are listed below:

- Acrylic (PMMA)

- Acrylonitrile butadiene styrene (ABS)

- Nylon polyamide (PA)

- Polycarbonate (PC)

- Polyethylene (PE)

- Polyoxymethylene (POM)

- Polypropylene (PP)

- Polystyrene (PS)